The Marmoraton Mine Fast Facts

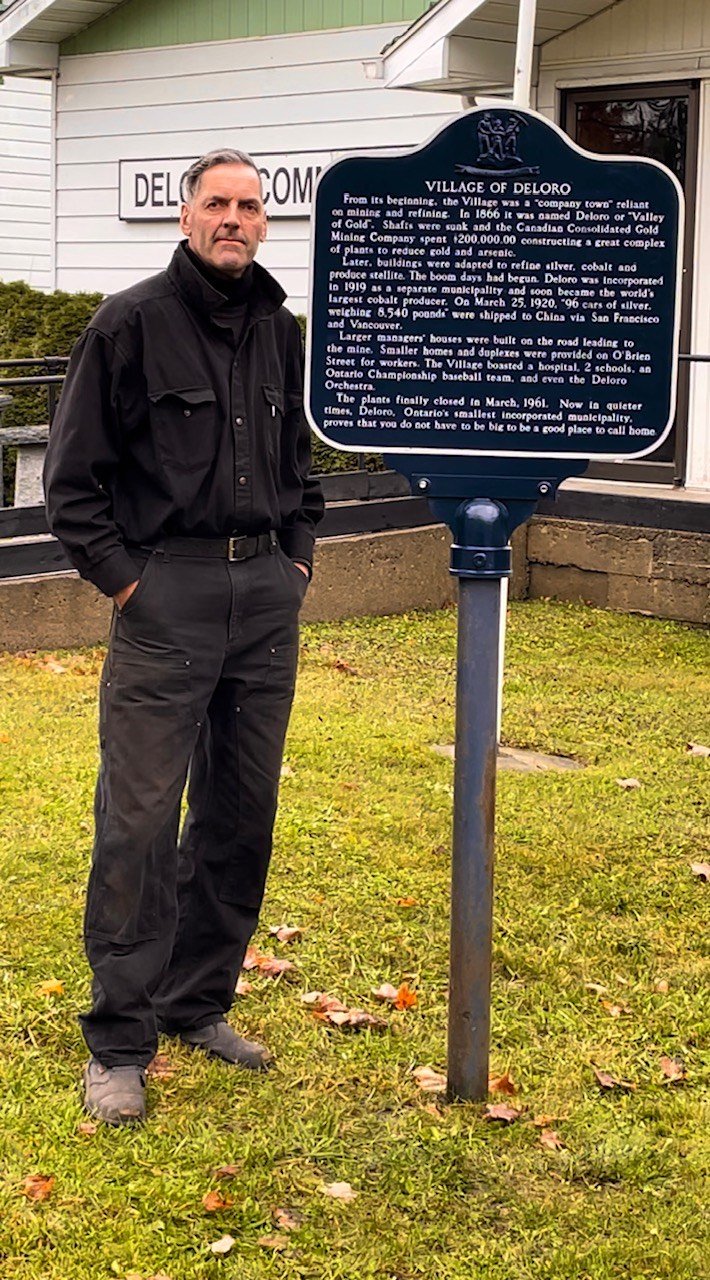

Photo by Jen Bennett

The magnetite ore body was discovered in 1948 by a government aeromagnetic survey, and the stripping of 130 feet of limestone overburden started in 1953.

The first shipment of iron ore pellets commenced in 1955, and eventually the mine employed 300 workers and support staff. It was owned by Bethlehem Steel Mills of Pennsylvania and exported iron ore pellets. The site was developed between 1951 and 1953.

Size of the pit: 2800 feet long, 1500 feet wide covering 75 acres with a depth of 700 feet. The average grade of the circular haulage road was 10%.

There has been a total of 70 million tons of waste rock removed from the pitand at the time, 2 ~ 250 HP pumps were needed to pump excess water from the pit for excavations to continue.

The breakup of the rock and ore was accomplished with sets of drilling patterns boring 7 inch holes 60 feet into the bedrock, and filled with 8 - 32, 000 lbs of explosive. Each blast could yield 20 - 80,000 tons of rock and ore.

Electric shovels used - 3 with 6 cu. yd. dipper, 1 with an 11 cu. yd. dipper....Dump trucks used - 6 ~ 105 ton with 1000 HP diesel electric drive, 2 ~ 55 ton with 635 HP diesel engines.

Annual production: 3.1 million tons of rock to produce 520,00 tons of pellets

Process: The iron ore containing magnetite is crushed and ground, magnetically separated to produce 65% iron concentrate, then converted by roasting into hematite pellets ( 3 crushers of 350 HP each, 2 rod mill grinders of 350 HP each and 2 ball mills).

The 2400 degree F. roasting took place in 4 vertical shaft furnaces 6 X 12 feet and 40 feet high.

A daily ore train of 30 to 35 cars took pellets south to Picton port for loading into the 25,000 ton ore boats.

Annual plant production: 520,000 tons of hematite.

Plant closed in 1978 as the price of iron dropped, and the bed or ore was heading deeper. Much of the equipment and some of the miners were relocated in Argentina. Some men moved to Elliot Lake, Ontario

AND HERE ARE ALL THE REST OF THE STATISTICS

MARMORATON MINE - 14 Sept 1967

PIT

• Discovered January, 1948 - Aero-magnetic survey

• Drilled 1950 - 40 holes, 460 to 1800' deep

• Began development Sept 1951 to clear land and March 1952 to start removing 20.5

million tons of limestone overburden 130' deep

• Began hoisting ore and operating plant 1955

• Pit is now 2800' long and 1500' wide x 500'deep. Will ultimately be 750' deep

• Benches are 45' and now 55' (lower benches)

• Expansion program - temp. roads - permanent entrance road

• Yearly production is 1Y4million tons ore

3% million tons waste

• Average ore contains 32% magnetic iron

• 3.5 million gals of water pumped from mine per week

• Half million gals of water pumped from mine per day = 21,000 gallons per hour = 350 gallons per minute

• Ore is hauled in 22 ton trucks, dumped into skips. Waste is hauled in 55 and 65 ton trucks to waste dumps

• Roads are 10% grades Truck cycle hauling waste is 3 miles - 15 mins.

DRILLING

• 3 Quarrymaster drills with air compressors, electric powered

~ 1 @ 200 H.P., 760 CFM

Y 2 @ 350 H.P., 1200 (FM

• Hammers are Down-the Hole type

• Bits are 7" dia., 14 ft/hour in ore

33 ft/hour in limestone

Life: 800' in ore

15,000' in limestone

• Holes are 50' to 60' deep and 20' apart

BLASTING

• Average blast is 35,000 tons of rock using 5 tons of powder. Some blasts are 65,000

tons rock

• Powder is Ammonium Nitrate packaged in containers of 25 Ibs. to fit the drilled holes

SHOVELS

• 2 - #4161

• 1- #151-M

• 1- #191-M

300 H.P., 4-~ or 6 cu. yd. buckets

400 H.P., 6 cu. yd. bucket

700 H.P., 11 cu. yd. bucket ($600,000)

TRUCKS

• 9 - 22 ton Euclid, 300 H.P. ($38,000 ea.)

• 8 - 55 ton Sicard, 635 H.P.

• 2 - 65 ton Sicard, 700 H.P. ($110,000 ea.)

• 1-105 ton Sicard, 1000 H.P. {$250,OOOea.)

• Tires on Sicard trucks are 21:00 x 35 size and cost $3,200 each

SUBSTATION

• Incoming voltage - 44,000

• Secondary voltage - 2,300

• Consume 3-% mil. Kilowatt hours/month - about $22,OOO/month

HOIST

• 12' dia. double drum counter-balanced, 2 skips, each hoisting 22 tons ore, 1250 H.P., 1-

%1} dia. ropes. Max. rope speed 800 ft/min. - 9 miles/hour

• Hoist operator on top of head frame

PRIMARY CRUSHER

• 48" Gyratory 3-~/I setting on closed side crushes ore to minus 5/1 size l-y,j" throw

• 48/1 conveyor to stockpile of max. 40,000 tons

• Tunnel- feeders and conveyor, 300 to 400 tons/hour

SECONDARY CRUSHING PLANT

• 5' X 12' triple screen

• Cobbing

• 5'-6 gryatory crusher set at lJ1 closed side W' throw

• 6' x 12 double screens

• Cobbing

• Hydrocone crusher set at 3/8" closed side, I" throw

• Waste or cobbed rock to waste bin

• Crushed ore to silos (750 tons each)

• 30% of ore is cobbed as waste rock. Waste rock is hauled to Armstrong crushing plant

for further crushing. Armstrong sells this rock for highway construction and railroad

ballast.

GENERAL

• 325 men are employed for whole plant. Additional 20 students are hired during

summer

MILL

• Two identical units

• Feed is 60 tons/hour for each unit - water is added

• Rod Mill: 8' - 101'2"x 12' - 0" long 350 H.P.

• Rods 3W' and 4" dia. X 12' - A" long

• Crushes or grinds to 10 mesh

• Ball Mill: 11' - 6" x 10' - 0" long, 600 H.P.

• Balls are 2" dia.

• Grinds to 60% minus 325 mesh - as fine as flour

• Slurry is pumped to 24" cyclone where it is classified, with the coarse material going

back to the ball mill via the hi-amp magnetic separator for further grinding. The finer

material (majority) goes to a box to be distributed to 4 sets of 3-drum permanent

magnetic separators where more waste is separated (called tails) - to 100' thickener

tank - water is reclaimed for re-usage-tails are pumped to tailings pond for settling.

• The fine iron concentrate (black) from is charge of mag. separators, which is now about

65% iron, is pumped to the pellet plant

• Make-up water comes from the mine drainage (345 GPM) and from Mud Lake(655 GPM)

BOILER ROOM

• 3 boilers: 2 @ 125 H.P., 1@ 200 H.P.

• Heating for all the buildings and hot water

• 3 Air Compressors: 2 @ 100 psi1 @ 30 psi

PIT BUILDING

• Iron Concentrate slurry from mill goes to 30' thickener or the storage pits (4 @ 1200

tons each). Pits are used for surge - mill shutdown or a 3 fce operation

• Underflow of thickener is pumped to top floor to filters

• Coke is added at rate of about 14#/ton to assist internal heating of the pellets

• Crane is for handling coke and feed to repulper

ELEVATOR

• Pellet plant consists of 4 furnaces with 2 or 3 operating at one time

• Object is to withdraw most of the water from the slurry by filtering, to form balls of

about W' in size and to make them hard for further handling and for blast furnace feed

at the steel mills

FILTERING

• Vacuum used to withdraw water

• Air to blow off cake

BALLING

• Bentonite - 12#/ton feed for binding

• Constant moisture content for balling

FURNACES - (4)

• 6' x 12' X 40' high

• 25 tons/hour each furnace

• Shuttle car feeds furnace evenly

• 1900 degrees F. combustion chambers

• Furnace is full at all times

• Same amount that is fed is discharged at bottom

• Heat zone is in upper 2 feet of furnace where the hardening takes place at 2400 deg. F.

• As the pellets move down the furnace they cool down to about 400 deg. F

• 5300 cfm of air to cool and heat pellets

DISCHARGE FLOOR

• Pellets too hot to touch

• Metal conveyors, oscillating to common conveyor to loading bin. Add water spray to

cool pellets

• Blowers for furnaces - 350 H.P., 5300 cfm air

• Regrind - Pellet screened over 1/8" screen - undersize to classifier - coarse material to

regrind ball mill. Fine material pumped back to 30 feet thickener - pit building

WALK OUT OF PELLET PLANT

• Loading bins -1770 tons

• 30 to 35 cars/day to Picton 64 miles away - 50 tons/car

PICTON

Stockpile during winter

Loaded onto boats of 12,000 to 25,000 tons capacity across lake Ontario to

Bethlehem's steel plant at lackawanna, N.Y., 211 miles away.

C. Wheeler